MECACONCEPT,

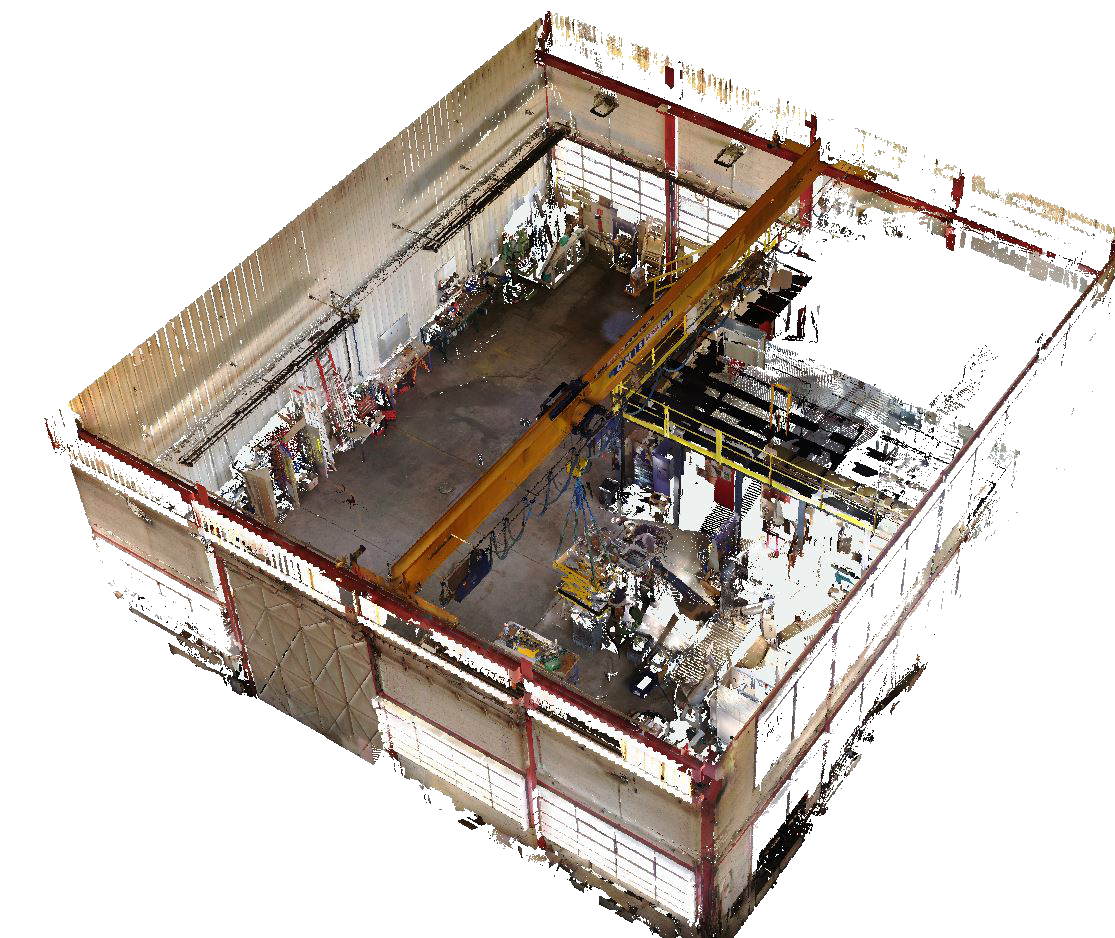

RELEVE LASER 3D - MODELISATION 3D

Fort de ses 30 années d'expériences en ingénierie industrielle, MECACONCEPT propose un service de modélisation 3D de l'existant, ateliers, bâtiments, skid..

Equipé de scanner FARO® Focus S70 et de logiciels experts, MECACONCEPT met ses compétences en ingénierie de conception au service de vos projets.

NOS PRESTATIONS : nuage de points, maquette numérique, rétro-conception

Avec les outils FARO, nous réalisons des mesures précises et détaillées de vos installations permettant la création et l’exploitation d’une maquette numérique 3D fidèle à la réalité.

Des prestations adaptés à vos besoins :

- Relevé sur site de vos bâtiments, ateliers et installations jusqu'à la pièce mécanique : acquisition de nuages de points et de photos HD sans interruption de la production. Récupération de toutes données utiles complémentaires ( valve, pompes...)

- Traitement des données numérisées : alignement et assemblage des nuages de points obtenus par les différents scan, filtrage, nettoyage et optimisation

- Extraction et exploitation des données selon vos projets : cotations et mesures, zonage, coupes, extraction de plans 2D, maquette numérique 3D

- Livraison de la copie numérique dans un format standard avec les logiciels CAO du marché ou visionneuse

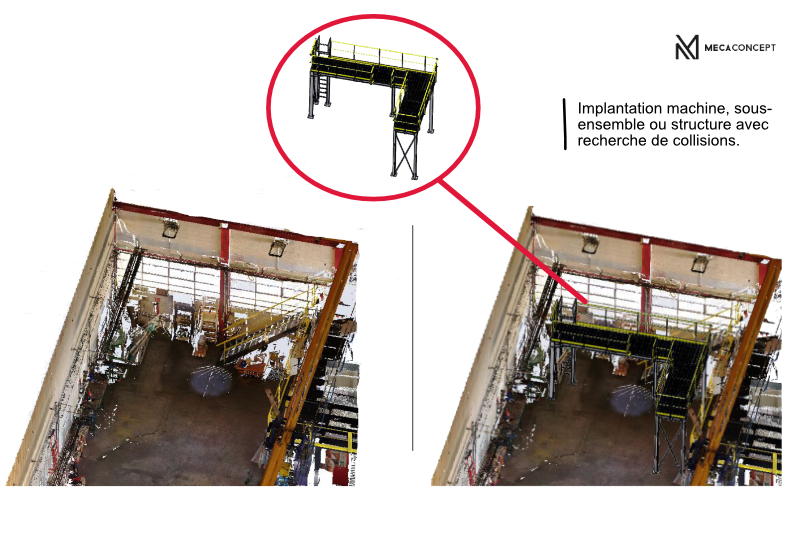

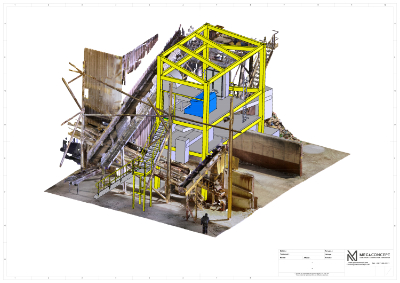

- Accompagnement de notre bureau d'études : rétro-ingéniering, détection de collisions entre un projet 3D et la maquette 3D TQC, étude d'implantation de lignes, mise en plans 2D et bien plus encore comme la possibilité de remontage du process jusqu'aux PID, l'analyse de déformation de structure métallique par nos ingénieurs calculs et même la rétro-conception de vos pièces de rechange ou d'usure...

NOS ATOUTS : DES OUTILS ET DES HOMMES

- une grande connaissance des milieux industriels et de leurs contraintes

- du matériel de pointe comme le FARO® Focus S70 pour effectuer des relevés complexes

- une maîtrise des outils CAO par notre bureau d'études

ACQUISITION

RAPIDE

Simple à mettre en oeuvre, le relevé de laser 3D est plus rapide que le relevé de côtes manuel avec un mètre laser. Vitesse d’acquisition d´environ 1 000 000 points par seconde pour le Faro Focus S70

PRÉCISIONS ET EXHAUSTIVITÉ

Avec le Faro Focus S70, la précision de mesures est de +/-1 mm même dans les environnements contraints ou difficiles d'accès. Avec lui, peu de risque d'oublier une côte ou une mesure !

EXPLOITATION DES DONNEES

Le nuage de points obtenu par le scan 3D offre, après retraitement, de nombreuses possibilités : plans 2D, modélisation 3D, maquette interactive

LOGICIELS EXPERTS

En tant que bureau d'études technique nous disposons de logiciels CAO performants : Solidworks, Scene, AVEVA PDMS, AVEVA E3D2, Catia

NOTRE EXPERTISE EN INGÉNIERIE

La force d'une équipe pluri-disciplinaire : ingénieurs calculs, projeteurs installation générale, chefs de projet conception mécanique, hommes de chantier

EXEMPLES d'APPLICATIONS

- Etablissement d'un dossier "Tel Que Construit" permettant de documenter l'existant en vue d'une transformation future.

- Rétro-édition de plans ou de modèles CAO 3D pour tout type d'installations apparentes : charpentes métalliques, tuyauteries, équipements divers…

- Simulation 3D de projets : vérifier et valider la faisabilité d'intégration d'un nouveau équipement dans l'existant, étude de collisions

- Réalisation de maquette 3D interactive : filtrer ou rechercher des éléments précis de votre installation

- Naviguer virtuellement dans vos installations existantes et projetées : visite virtuelle à 360°

simulation de projet : recherche de collision

étude d'implantation charpentes métalliques et équipements