MECACONCEPT,

END-OF-LINE SOLUTIONS, PACKAGING, ORDER PICKING, STACKER CRANES, INTRALOGISTICS FLOW MANAGEMENT

At Mecaconcept, we focus on developing flexible, modular solutions. Our priority is to meet your expectations today, while leaving the door open to tomorrow's developments.

BECAUSE YOUR BUSINESS IS UNIQUE

we can customize your end of line to suit your needs!MODULAR PACKAGING LINE

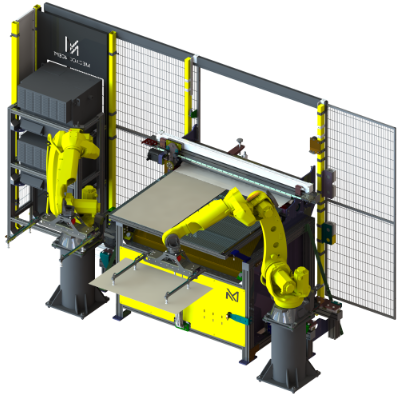

DESCRIPTION:

The packaging line is made up of independent sub-assemblies interfaced with each other. For example: carton erector, separator installation, vertical product packaging, additional elements such as warranty cards or installation instructions, box closing unit with printing and labeling.

GOOD TO KNOW :

- Rigid products are picked and packed in batches by a top-load robot. Accessories are deposited using vibratory bowls and sets of cylinders and suction cups.

- The integration of marking systems (labeler, printer) during the packaging process enables various data to be affixed to the boxes, including serialization.

- The highly intuitive operator interface ( HMI ) centralizes control of the various modules.

Additional peripherals can be added:

- camera-based quality control ⇒ detection and elimination of non-conforming products.

- information traceability ⇒ data recording in management software (ERP)

- palletizing module

BENEFITS :

Packaging lines tailored to your needs:

- Compact

- Modular

- scalable

- easy to integrate

LINE ENGINEERING

With 30 years' experience in process engineering and special machines, MECACONCEPT's design office can provide you with the expertise you need to build complete lines, with or without existing equipment.

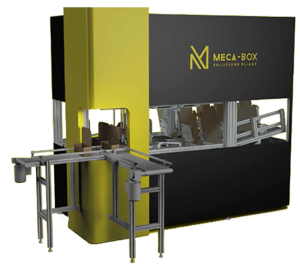

MECA-BOX: AUTOMATIC CARTON ERECTOR

Automated solution for your retail packaging:

Automatic folding and forming of cardboard boxes without glue or staples

FEATURES :

Configurable to your needs:

- developed on the basis of fefco 0470 and 0471 folders

- 1 or 2 magazines for loading unfolded cartons

- single-track or double-track forming machine

- production speed of 5 to 8 cartons/min.

- compact and configurable to your needs

- can be easily integrated into a packaging line

- ergonomic design

MECA-CUTTING: CUTTING OF PAPER INTERLEAVES INTO ROLLS

Automatic cutting machine for rolls of paper dividers:

The MECA-CUTTING cutting machine produces dividers in the desired format from a roll of paper. Configurable according to your needs, this machine integrates perfectly into your automated packaging and/or palletizing line.

BENEFITS :

- Flexible: cut dividers to any desired size

- Easy integration into a packaging/palletizing line

- Automated management of format changes: centralized control from the packaging/palletizing line or from the machine's HMI

- Compatible with all makes of outfeed robot

- Compact: reduced footprint

- Reel width: up to 1200mm

- Speed: up to 10 dividers/min in 600*800 mm format

- Paper reel weights from 40 to 200g/m².

- Max. roll weight: 1000 Kg

- Max. roll diameter: 1100 mm

- On-demand divider cutting format: automatic format changeover or from HMI

- Configurable audible and/or visual end-of-roll warnings

CONFIGURABLE ACCORDING TO YOUR NEEDS

- Integration of a longitudinal cutting system

- Choice of supply brand on request ( Siemens, Schneider... )

- Coil mounting with or without expanding shaft

- Integration of an antistatic device

AUTOMATED ORDER-PICKING SOLUTION

DESCRIPTION :

BENEFITS :

- reduced order-picking time: this "GOODS TO MAN" technique limits operator movements.

- compact, modular warehouse adapted to your company's needs.

- simplified management thanks to an intuitive user interface: new product references are added directly by the operator, who simply specifies the location and dimensions of the product. The rest is automatically managed by the system.

- operating flexibility: continuous flow and/or deferred flow. For example, orders can be processed as they come in during the day, and in batches at night. This means that early in the morning, the operator only has to check and pack orders prepared automatically overnight.

- customized IT development: interface with ERP databases and other companies or external services such as COLISSIMO WEB SERVICE.

CUSTOMIZED AUTOMATED STORAGE

YOUR EXPECTATIONS

- Optimize storage volume

- Improve inventory and flow management

- Improve working conditions for your employees

- Reduce your operating costs

REALIZATION EXAMPLE: STACKER CRANE FOR LONG PRODUCTS

Vertical automated warehouse, a solution suited to the storage and handling of bulky, elongated goods.

DESCRIPTION :

Automated stacker crane for managing production flows between different workstations for bulky metal parts such as steel strips, sheet metal or bars... Vertical, secure storage interfaced with the customer's ERP system.

EMPLOYEE TECHNOLOGIES :

- innovative mechanical design of compact, telescopic lifting system

- 2-axis mobile gripper with travel speeds of 800 mm/sec horizontally and 200 mm/sec vertically

- positioning repeatability of the order of 1/2 mm

- system equipped with a flow optimization module interfaced with the customer's ERP system

- simple, intuitive HMI

The entire system ( mobile gripper, cantilever and IT interface ) is fully configurable to customer requirements.

BENEFITS :

- fully configurable to customer requirements

- optimized storage space

- operator ergonomics and safety

- easy handling

- simplified inventory management

- workflow module interfaced with customer ERP system

- intuitive, customizable HMI

- time saving.

TESTIMONIAL

One of the benefits of the MECACONCEPT solution is that it is fully interfaced with our ERP in real time.