#1 How to make a success of your first robotization project? part 2

How to make a success of your first robotization project?

publication: March 2021

reading level: easy

target audience: all audiences

reading time: 4 minutes

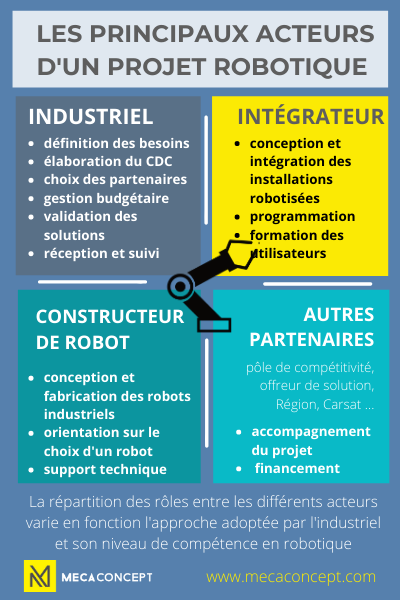

FOCUS ON THE ROLE OF THE INTEGRATOR

Integrators play a key role in the value chain of a robotic project. And yet their profession is sometimes unrecognized ...

If we ask manufacturers to name players in the world of robotics, they will spontaneously cite major manufacturers such as STAUBLI, FANUC, KUKA, Universal Robots, etc .... But , few of them mention their local partners who are the integrators.

This is paradoxical because a robot delivered as is is a naked entity, incapable of doing anything on its own. The success of a robotics project is moreover largely conditioned by the design and the implementation of the complete position in his work environment.

In France, in the majority of cases this mission is entrusted to an integrator (often of the VSE / SME type) with strong technical know-how. Focus on a profession that is sometimes overlooked ....

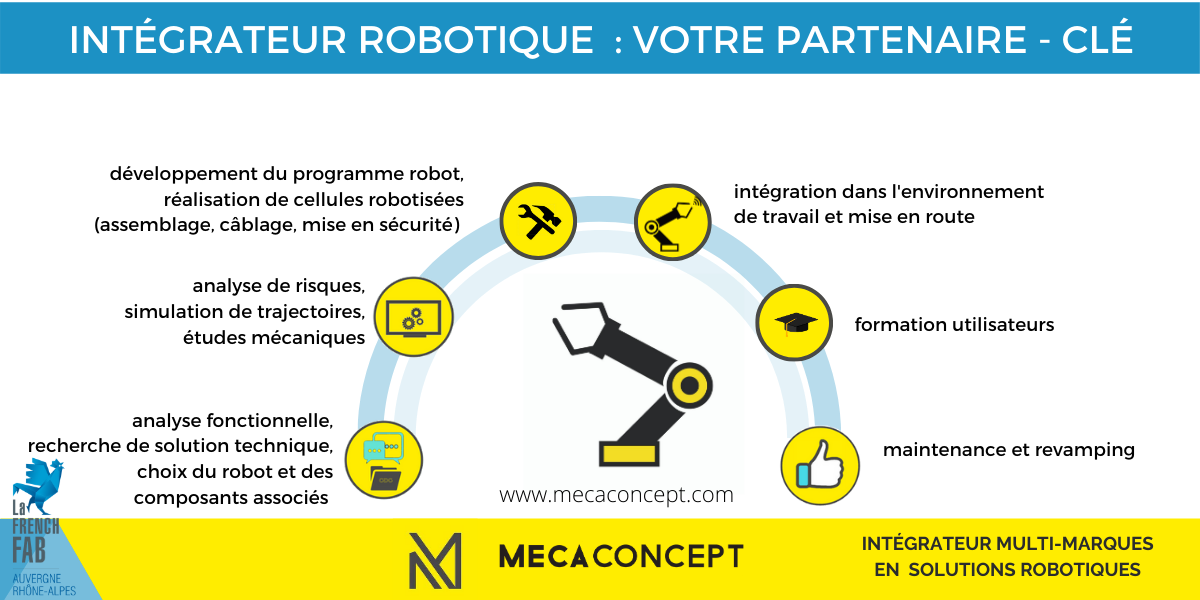

MISSIONS OF A ROBOTIC INTEGRATOR

The job of an integrator is to develop a turnkey robotic solution. Each project being unique, the integrator offers the robot best suited to customer needs and is responsible for deploying it in its industrial environment.

Often in addition to his robotic skills, the integrator has the ability to develop complete industrial equipment . He carries out the risk analysis and takes charge of the design, production and integration of all the elements necessary for its proper functioning (gripper, sensors, material and immaterial barriers, etc.). All in compliance with the safety standards and "machine" directive in force, of course!

It is therefore a field of activity which requires many complementary skills as well as a good knowledge of the customer process as a whole.

INTEGRATOR / INDUSTRIAL: A RELATIONSHIP OF TRUST FOR SUCCESSFUL COOPERATION

Creator of Turnkey Solutions Industry of the Future:

Specialized in industrial engineering, MECACONCEPT has advanced expertise beyond robotic programming:

- process automation project management,

- mechanical design,

- automation of upstream, downstream devices

- machine vision

- industrial computing

"We mobilize all of our skills to serve your projects"

more informations

You will understand that if you do not have the internal resources to carry out a robotic project, you would most likely have to work with an integrator. Choosing an integrator means choosing a partner capable of supporting you in the change.

Tips for selecting your integrator

In France, there are nearly 450 integrators. A pre-selection is necessary.

Here are some avenues for reflection that may guide your consultations:

-

the partner's expertise in the user's industry. This is reflected in his experience through similar achievements as well as his knowledge of the industrial process. The levels of complexity and requirement vary depending on the application to be robotized but also on its environment. example: particularity of equipment and installations in ATEX zone, clean room, humid environment.

-

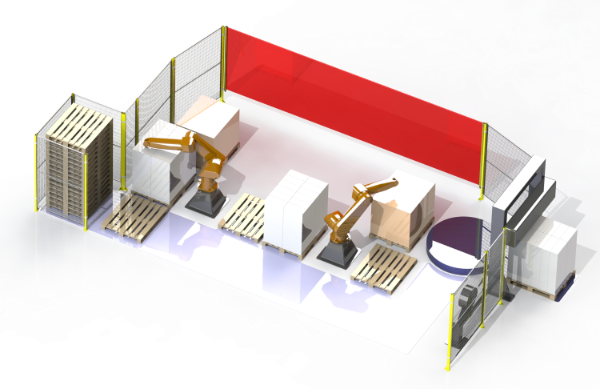

the capacity and skills of the partner to take charge of a more global automation project in which the robot is an element of the process. examples: end-of-line automation integrating top-load robots or palletizing robots / production of installations with machine vision (unhooking of parts, recognition of objects, etc.) In this case, it may be judicious to favor a single point of contact for the entire project.

-

the geographical criterion: For the majority of simple applications such as end-of-line palletizing, geographical proximity facilitates commissioning and various interventions. However, if you are planning to deploy your cells abroad or if you need an ultra-cutting-edge robotic application, make sure that the local structure approached really has the capacity to support you. And yes, geographical proximity turns out to be a "true-false" criterion of choice!

When examining the offers, it is likely that the technical and commercial solutions diverge significantly. The technical choices may indeed vary d ' one integrator to another. For the same project, several solutions are possible. So how do you navigate it?

First, check what is included (or not) in the commercial proposal and AVP (Draft). In general the more detailed the AVP, the more The integrator's reflection has been technically and financially advanced. It is a guarantee of seriousness. But beware, this AVP is the result of the work of the integrator and from an ethical point of view, it is inappropriate to communicate it as it is to others with a view to reorienting debates or calibrating budget proposals. Each solution defends itself and it is up to the integrator to demonstrate its merits. Play the game!

Do you still have doubts about robot cycle time and industrial organization choices? Have the solution validated by performing a flow simulation integrating the robotic solution interfaced with upstream / downstream equipment . You thus secure your choices as well as your ROI (Return On Investment).

If you still have hesitations, don't hesitate to ask them about:

- the risk analysis to be carried out. As a reminder in industrial robotics and cobotics, security and standards compliance in effect are crucial. The risk analysis is therefore an essential step in a robotics project from which the integrator cannot derogate.

- by the way, will the equipment be (or not) certified as compliant by an independent body such as APAVE, DEKRA?

- and is the training offered to staff referenced DATADOCK ? (pledge of seriousness and possibility of support by your OPCO)

All these exchanges make it possible to build the bases of a solid collaboration between industrialist and integrator.

CONDUCT of a ROBOTICS project Led by an INTEGRATOR

ANALYSIS

Functional analysis, risk analysis, mechanical and electrical studies, robot program development and trajectory optimization. Milestone: receipt and validation of studies by the manufacturer.

DESIGN

Realization, programming and tests Milestone: provisional acceptance at the integrator. This phase validates the equipment and its operation before it is transferred to the manufacturer.

ON-SITE INTEGRATION

Commissioning of the equipment in its environment and validation of its dynamic operation. Milestone: final acceptance by the user. Transfer of ownership and start of the guarantee

TRAINING

Training of operators and maintenance staff on site. Possibility of financing by OPCO if the integrator is referenced datadock

MAINTENANCE

according to the assistance modalities agreed between the parties.

"At Mecaconcept, t all our equipment is built according to the 2006/42 / ce machine directive and other technical specifications referenced in force. And we regularly rely on independent organizations to certify our solutions . "

You like this page ?

A project ?

SHARE IT !